- Home Page

- Company Profile

-

Our Products

- Banner Models

- Banner Sensor QS18EP6CV45

- Banner Sensor QS186LE

- Banner Sensor QS18VP6FF200

- QS18VP6FF100 Banner Sensor

- QS18VP6R Banner Sensor

- Banner Sensor Q12AB6FF30

- BANNER SENSOR QS18VP6LP

- BANNER SENSOR QS18EN6CV45

- QM42VT1 Banner Temperature and Vibration Sensor

- Banner QS18VN6FF50

- QM42VT2 Banner Temperature and Vibration Sensor

- QS18VN6D Banner Sensor

- Banner Tower Light TL50GYR Non Audible

- Banner Sensor QS30

- Banner Sensor QS18VP6LPQ8

- Banner Column Light CL50GRXPQ

- Banner Sensor QS18VP6FF50

- Banner Sensor QS18VN6LP

- QS18VN6FP Banner Sensors

- QS18VN6R Banner Sensor

- QS18VN6CV45 Banner Sensor

- QS18VP6CV45 Banner Sensor

- QS186LE12 Banner Sensor

- QS18VP6D Banner Sensors

- QS18VP6FP banner Sensors

- QS18VN6FF100 Banner Sensor

- Banner Ultrasonic Sensor T30UXIC

- BANNER ULTRASONIC SENSOR T30UXIA

- Q4XTILAF300-Q8 Laser Sensors

- Kubler Models

- 8.5000.8621.0500 Kuebler Encoder

- 8.5020.8551.1024 Kuebler Encoder

- 8.5020.4A51.1024 Kuebler Encoder

- 8.5020.855A.1024.0030 Kuebler Encoder

- 8.5000.855B.1024.0030 Kuebler Encoder

- Kubler Slip Ring SR060E-25-2-2-132-V100

- 8.5000.835A.1024.0050 Kuebler Encoder

- Kubler Slip Ring SR060E-20-2-2-132-V100

- 8.KIS50.835A.1024.0030 Kuebler Encoder

- 8.KIH50.D35A.0360.0030 Kuebler Encoder

- 8.5020.8A21.1024 Encoder

- 8.5000.835A.2500.0050 Encoder

- 8.5020.8854.1024 Encoder

- 8.5020.8551.5000 Encoder

- 8.KIH50.D821.1024 Encoder

- 8.5020.835A.1000.0050 Encoder

- 8.5020.4A5A.1024.0050 Encoder

- 8.5020.D35A.1024.0030 Encoder

- 8.5020.435A.1024.0050 Encoder

- 8.5000.8552.1024 Encoder

- 8.5000.8551.1024 Encoder

- 8.5020.4551.1024 Kuebler Encoder

- 8.5000.8552.5000 Kuebler Encoder

- Kuebler 8.5020.4A21.1024 Encoder

- Kuebler 8.5020.4351.1024 Encoder

- KUEBLER PRODUCTS

- Kuebler Inclinometer

- 8.KIH50.D54A.2048.0015 Incremental Encoders

- Kubler Hollow Shaft Encoder

- Incremental Encoders

- Kuebler 8.5020 Hollow Shaft Encoder

- 8.KIH50.D851.0360 Incremental Encoders

- Kuebler Absolute Encoder

- Kubler Rotary Encoder

- Kuebler Slip Ring

- Bearing Less Encoder

- Encoder Kubler

- Draw Wire Encoder( Kuebler / Kubler )

- Linear Magnetic Encoder

- HOUR METER

- Kubler Incremental Encoder

- 8.KIH50 Encoder

- Kubler Bearing Less Encoder

- 8.KIH40 Encoder

- Kubler 8.5000 Encoder

- Kubler Sendix 5000 Incremental Encoders

- Kuebler Encoder

- Kuebler Encoder 8.5020.4A51.1024

- Kuebler Encoder 8.5020.D35A.1024.0030

- Kuebler Incremental Encoder

- 8.5000.855B.1024.0030 Incremental Encoders

- 8.5000.855B.1024.0050 Encoder

- 8.5000.B14B.2500.0050 Encoder

- 8.5020.4321.1024 HOLLOW SHAFT

- 8.5020.4851.0512 HOLLOW SHAFT

- 8.5020.835A.0360.0050 Incremental Encoders

- 8.5020.835A.1000.0050 Incremental Encoders

- 8.5020.8854.1024 Incremental Encoders

- 8.5020.8A4A.4096.0100 Incremental Encoders

- 8.KIH50.4321.1024 Incremental Encoders

- 8.KIH50.4851.0512 Incremental Encoders

- 8.KIH50.4A51.1024 Incremental Encoders

- 8.KIH50.835A.1000.0020 Incremental Encoders

- 8.KIH50.835A.1000.0050 Incremental Encoders

- 8.KIH50.8551.1024 Incremental Encoders

- 8.KIH50.8811.1024 Incremental Encoders

- 8.KIH50.D35A.1024.0030 Incremental Encoders

- 8.KIH50.D521.1024 Incremental Encoders

- 8.KIS40.1642.0360 Incremental Encoders

- 8.KIS50.835A.2500.0050 Incremental Encoders

- 8.KIS50.835A.4096.0050 Incremental Encoders

- 8.KIS50.835A.5000.0050 Incremental Encoders

- BANNER PRODUCTS

- High Performance Long Range Sensor

- Banner Slot And Fork Sensor

- Banner QS18 Photoelectric Sensor

- BANNER DOME LIGHT K50LGRA2YP

- Color Mark Sensor

- Laser Sensor

- Vibration and Temperature Sensor

- Banner Safety Laser Curtain

- Banner Tower Light

- Q3X Series Laser Contrast Sensor

- Banner Q4XTBLAF300-Q8 SENSOR

- Banner Vision Lighting Sensor

- Long Range Photo Electric Sensor

- Banner Optical Sensor

- Banner Make Non Contact Temp And Humidity Sensor

- Fiber Optic Sensor

- Banner Part Verification Array

- Banner Fibre Amplifier DF-G1-PS-2M

- Banner Safety Controllers

- Banner Ultrasonic Sensor

- Vibration Sensor System

- Datalogic TLu-011 Sensor

- Banner Safety Light Curtains

- Ultrasonic Sensor Banner

- Autonics Photoelectric Sensor

- Laser Distance Measurement Sensor LTF

- QM30VT2 Banner Temperature and Vibration Sensor

- SR-IM-9A Safety Relays

- Infrared Temperature Sensor

- TEMPERATURE SENSOR M18TUP14Q

- Banner Fiber Optic Sensor DFG1

- PIRS1X166 UMPMAL

- LS2TR30 450Q8

- Indicator Light

- Registration Color Mark Sensor Banner

- IAT43ST5TA VL

- Pull Cord Switch

- Banner IVU Camera Sensor

- Vibration Sensor System QM30VT2

- Banner TL50GYRQ Convenient Tower Lights

- BWC-1MRSFRSB4 Antenna Cable

- PIZZATO Rope Pull Switches

- Banner Wireless Temperature Humidity Sensor

- Lighting Demo Box

- MQDC-415 Female Connector

- Banner Q26PLUMQ5 Luminescence Sensor

- Banner Luminescence Sensors

- Cordset A Code

- SAC-4P-2,0-PVC M12FS

- Q12RB6RQ Photoelectric Sensor

- Banner Vibration Sensor

- Machine Tower Light

- PBT46U VL Diffuse Sensor

- Banner Make Label Sensor Model No SLC1BB6

- Banner TL50GYRA Audible

- Banner Fiber Optic Sensor DFG1

- Banner K50LGRA2YP DOME LIGHT

- Banner Q3X Series Laser Contrast Sensor

- Banner Rugged Q4X Laser Displacement Sensor

- DF-G2-PC-2M BANNER

- IAT43ST5TA-VL Fiber Optics Sensor Heads

- PBT46U-VL Banner Sensor

- Q4XTILAF100-Q8 Stainless Steel

- Phoenix Contact

- Industrial Ethernet Switch - FL SWITCH SFNB 8TX - 2891002

- EO-D/UT - Socket 0804000

- ETHERNET SWITCH

- FL SWITCH 1005N - Industrial Ethernet Switch

- Sensor-Actuator Cable - Sac-4p- 2,0-E20-m 8fr

- Safety Relays CS AR-05V024

- Feed-through terminal blocK

- Panel Feed Throw Terminal Blocks

- Industrial Ethernet Switch 4 Port 1 Extra

- Industrial Ethernet Switch 8 Ports

- SMPS or Power Supply Unit 5A

- Single channel Slim Relay module

- Double Channel Slim Relay

- Relay Module 24 VDC 2CO

- Plug-In Industrial Relay

- Relay Base For 4 Co Contacts

- Slim Relay Module 230 VAC Single Channel

- Uninterruptible Power Supply

- Fuse Modular Terminal Block

- Single Relay

- Power supply unit

- Sensor-Actuator Cable - Sac-4p- 5,0-E20-m 8fs

- Sensor-Actuator Cable - Sac-4p- 3,0-Pvc-M12fs

- RJ45 connector - VS-08-RJ45-5-Q-IP20

- Slim Relay Module Double Channel 230 VAC

- Multi-Level Terminal Block

- Sensor-Actuator Cable - Sac-4p- 5,0-Pvc-M12fr-3l

- Sensor-Actuator Cable - Sac-4p-10,0-Pur-M12fs Sh

- SMPS POWER SUPPLY UNIT

- Feed-through terminal block - UK 16 N

- Fuse modular terminal block - UK 6,3-HESI

- Feed-through terminal block - ST 4

- Fuse Modular Terminal Block TB4 HESILA 250 (5X20) EI

- Hybrid motor starter - 2900574

- Single relay - REL-IR-BL-L- 24DC-2X21

- Fuse Modular Terminal Block TB4 HESILA 250 (5X20) EI

- Industrial Ethernet Switch 4 Port 1 Extra

- Industrial Ethernet Switch

- PHOENIX FL SWITCH 1005N

- Power supply unit - ESSENTIAL-PS-1AC-24DC-480W-EE

- Single channel Slim Relay module

- Power supply unit - QUINT-PS-1AC-24DC-5

- Power supply unit - TRIO-PS-1AC-24DC-10

- Sensor-Actuator Cable - Sac-4p- 3,0-Pvc-M12fs

- Sensor-Actuator Cable - Sac-4p- 2,0-E20-m 8fr

- Sensor-Actuator Cable - Sac-4p- 5

- Sensor-Actuator Cable - Sac-4p-10

- SMPS POWER SUPPLY UNIT

- SMPS or Power Supply Unit 5A

- Single Relay - REL-MR-24DC-21 - 2961105

- Phoenix Slim Relay

- Interlock Switches

- schmersal ZV7H 236-11Z-RMS

- BNS 260-11Z-ST-R

- PIZZATO ROPE SWITCHES FD2093-M2

- Solenoid Interlock Switch

- Schmersal Limit Switch

- SCHMERSAL BNS 260

- schmersal ZQ 900-11

- SCHMERSAL ZI232-FH11

- SCHMERSAL BNS 260-11Z-ST-L

- schmersal ZS 232-11-1-2888

- Safety Light Curtains

- Reer Metron ME 150 C

- Reer EOS2

- Buzzer E61IS6B1PV1B

- SAFETY LIGHT CURTAIN

- EOS2 303 A

- SAFETY LIGHTCURTAIN

- REER SAFETY LIGHT CURTAIN

- EOS2 753 A

- TZMCW24VDC Interlocking Switches

- SOLENOID INTERLOCK SWITCH SCHMERSAL

- Pull-wire emergency stop switches

- Turck Products

- Process Instruments

- REER PRODUCT

- EOS4 151 A

- EOS2 1053 A

- EOS4 1351 A

- EOS2 A 1353

- EOS4 1651 A

- EOS4 1801 A

- EOS2 1203 X

- EOS4 751 A

- EOS2 153 A

- SAFETY RELAY MOSAIC MR4

- EOS2 903 A

- EOS2 1203 A

- EOS2 1503 A

- EOS4 301 A

- EOS4 451 A

- EOS4 601 A

- EOS4 901 A

- EOS4 1051 A

- EOS4 1501 A

- Safety Light Curtain Admiral Ax 2b

- Safety Relay

- MEMORY CARD

- Reer Safety Light Curtain

- pizzato product

- KELLER PRODUCT

- KUEBLER Incremental Encoder

- 8.KIH50.835A.1000.0020 Incremental Encoders

- Kubler Incremental Encoders

- Kubler Incremental Rotary Encoder

- 8.5020 Kuebler Encoder

- Solid Shaft Incremental Encoder

- Kubler Incremental Rotary Encoder

- Kubler Encoder

- Kuebler Absolute Encoders

- 8.KIS40.1642.0360 Kuebler Encoder

- 8.KIH50.D54A.2048.0015 Incremental Encoders

- 8.5000.835A.1024.0020 Incremental Encoders

- 8.KIH50.835A.1000.0050 Incremental Encoders

- 8.KIH50.8551.1024 Incremental Encoders

- 8.KIH50.4A51.1024 Incremental Encoders

- 8.KIS50.835A.5000.0050 Incremental Encoders

- 8.KIH50.D521.1024 Incremental Encoders

- 8.5000.855B.1024.0050 Incremental Encoders

- 8.KIH50.8811.1024 Incremental Encoders

- 8.KIH50.D851.0360 Incremental Encoders

- 8.KIS50.835A.2500.0050 Incremental Encoders

- 8.5020.4321.1024 Incremental Encoders

- 8.5020.8A4A.4096.0100 Incremental Encoders

- 8.KIH50.4321.1024 Incremental Encoders

- 8.KIS50.835A.4096.0050 Incremental Encoders

- 8.5000.B14B.2500.0050 Incremental Encoders

- 8.KIH50.D35A.1024.0030 Incremental Encoders

- 8.KIH50.4851.0512 Incremental Encoders

- 8.5020.835A.0360.0050 Incremental Encoders

- 8.5020.4851.0512 Incremental Encoders

- 8.5000.835A.4096.0050 Incremental Encoders

- Photoelectric Sensor

- Micro Photoelectric Sensor

- HIGH SPEED ULTRASONIC SENSOR QS18UPA

- Photoelectric Beam Sensor

- Sick Photoelectric Sensor

- Banner Photoelectric Sensor

- Banner Temperature Sensors

- Photoelectric Distance Sensor

- Photoelectric Sensor

- OBT500-18GM60 E5

- Banner Photoelectric Sensor QS18VN6FF200

- Banner Sensor

- Temperature Indicators

- Exor HMI Touch Panel

- Banner Column Light

- Banner Q12AB6FF30

- Banner CL50 Column Light

- Banner Column Light

- Banner Dome Lights

- Banner Laser Sensor Q4XTBLAF300-Q8

- Banner Photoelectric Sensor QS18EN6CV45

- Banner Photoelectric Sensor QS18EP6CV45

- Banner Photoelectric Sensor QS18VN6D

- Banner Photoelectric Sensor QS18VN6FF50

- Banner Photoelectric Sensor QS18VP6FF100

- Banner Photoelectric Sensor QS18VP6FF200

- Banner Photoelectric Sensor QS18VP6LP

- Banner Photoelectric Sensor QS18VP6R

- Banner Q12AB6FF30

- Banner Q4XTILAF300-Q8 Stainless Steel Analog Laser Sensor

- Banner QS18 Photoelectric Sensor

- Banner QS18VN6FF100 Photoelectric Sensor

- Banner QS18VN6R Photoelectric Sensor

- Banner Ultrasonic T30UXIC Proximity Sensors

- Datalogic TLu-011 Sensor Registration or Eye mark sensor

- Hokuyo Safety Laser Scanner Sensors

- PHOTOELECTRIC SENSOR QS18VN6CV45

- QS186LE12 banner Sensor

- QS18VP6CV45 Banner Sensor

- QS18VP6D photoelectric sensor

- Qs18vp6fp Banner Sensor

- TL50WBGYRQP TOWER LIGHT

- Dimensional Inclinometer

- Turck Contactless Encoder

- Sensor-Actuator Cable - SAC-4P- 5,0-PVC-M12FR-3L

- Power supply unit

- Metal Slot Sensor

- Relay Module - PLC-RSC- 24DC-21-21

- INDUCTIVE PROXIMITY SENSOR

- Turck Capacitive Proximity Sensors

- Kuebler Slip Ring SR060E-20-2-2-132-V100

- Kubler SR085 Slip Rings

- Limit Switch Schmersal

- OBT 200 18GM60

- 360 Degree Kubler IN88 CANopen 1 Dimensional Inclinometer

- Data Acquisition Interface

- Position Transducers -LVDT

- Kubler IN88 CANopen 2 Dimensional Inclinometer

- 360 Degree Kubler IN81 Inclinometer

- Continuous Plug-In Bridge - FBST 500-PLC BU

- Continuous Plug-in Bridge - Fbst 500-plc Rd

- Kubler IN88 Modbus 1 Dimensional Inclinometer

- Kubler IN88 2 Dimensional Inclinometer

- SCHMERSAL SAFETY MONITORING MODULE - SRB031MC- 24V-1.1SEC

- Banner Ultrasonic T30UXIA Proximity Sensors

- BNS 260-11Z-ST-L SCHMERSAL

- BNS 260-11Z-ST-R Position Switches

- BNS260-11Z-ST-R SCHMERSAL

- Kubler IN81 2 Dimensional Inclinometer

- Kubler IN88 Modbus 2 Dimensional Inclinometer

- 360 Degree Kubler IN88 1 Dimensional Inclinometer

- Draw Wire Encoder

- Proximity Sensor DK20-9,5-110-124(418074)

- Kubler C100 Draw Wire Encoder

- Kubler A40 Draw Wire Encoder

- Kubler C60 Draw Wire Encoder

- Kubler D120 Draw Wire Encoders

- Kubler A41 Draw Wire Encoder

- Kubler B75 Draw Wire Encoder

- Kubler B80 Draw Wire Encoder

- Kubler C105 Draw Wire Encoder

- Kubler C60 Draw Wire Encoder

- Kubler A50 Draw Wire Encoder

- Kubler C100 Draw Wire Encoder

- Kubler D125 Draw Wire Encoder

- Kubler D120 Draw Wire Encoder

- Kubler B80 Draw Wire Encoder

- Kubler A30 Draw Wire Encoder

- Proximity Sensor DK20-9

- SCHMERSAL

- Bearing less Encoders

- CORD SETS

- Orchid Products

- Shaft Copying Systems

- ULTRASONIC SENSOR

- TOWER LIGHT

- STRIGHT ACTUATORS

- Colour Marks Sensor

- Retro Reflective Tape

- Solar Acdb

- Solid State Relay

- Interlocks

- Emergency Stop Switch

- Foot Switches

- Terminal Block

- Inductive Proximity Sensors Rectangular

- Honeywell Power Relays

- Industrial Sensors

- Label Sensor

- Limit Switch

- PANEL DOOR SWITCH

- Relay module

- Icotec

- ICOTEC

- KEL-ER-B4 Part no.48204 cable frame

- KVT 40 Gy – Part No. – 45203

- KVT 63|4 Gy – Part No. – 45215

- KVT 63|1 Gy – Part No. – 45212

- KVT 20 Gy – Part No. – 45034

- KVT 25 Gy – Part No. – 45035

- MB 6 C-T 200 M4

- MB 10 C-T 200 M5

- MB 16 C-T 1000 M8

- KEL-DPU 24|21 Gy

- KEL-DPU 24|17 Gy

- KEL-ER 24|10

- KEL-ER-B4 : Part No. – 48204

- Icotecc

- ICOTECc

- Icotec Product

- IDEC

- Banner Models

- Contact Us

Banner Part Verification Array

75000 INR

Product Details:

- Weight Approx. 1.2 kg

- Control Type Electronic

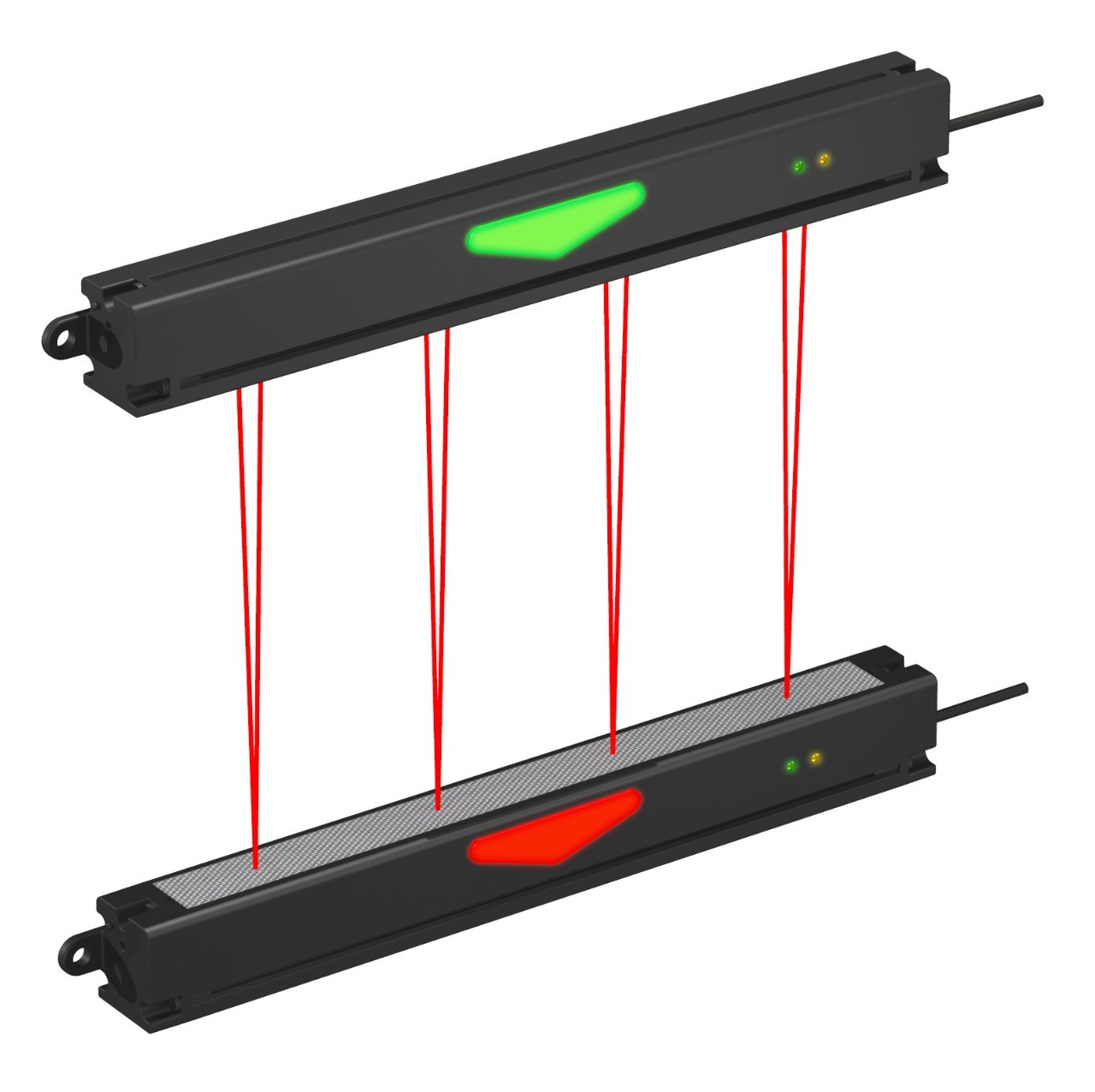

- Sensor Type Infrared Emitter and Receiver Array

- Drive Type Direct Drive Electronic

- Connectivity Type Wired

- Phase Single Phase

- IP Rating IP65

- Click to view more

X

Banner Part Verification Array Price And Quantity

- 75000 INR

- 1 , , Pack

Banner Part Verification Array Product Specifications

- Infrared Emitter and Receiver Array

- Direct Drive Electronic

- Up to 2000 Parts/Minute

- 50-60 Hz

- Single Phase

- Wired

- 2 meters

- IP65

- Electronic

- Approx. 1.2 kg

- 10 to 30 V DC

- -20°C to +55°C

- 24V DC

- Industrial Grade Plastic and Aluminum Housing

- Integrated High-Speed Processor

- Fast Response, High Accuracy, Easy Integration, LED Status Indicators

- Automatic

- Bracket or Panel Mounted

- Part Detection, Inspection, and Verification in Assembly Lines

Banner Part Verification Array Trade Information

- 4-6 Week

Product Description

Banner Part Verification Array

Highly visible pick and mis-pick indication with mounting versatility.

- More cost-effective coverage with the highest reliability

- Opto-mechanical alignment with bright red emitter beams allows for easy setup

- Easy installation with no assembly required

- Can mount directly to racking profile vertically or horizontally

- Rugged, all-metal compact housing for high durability

- Highly visible, two color integrated job LED arrows for confirmation of correct pick or indication of mis-pick

- Retroreflective tape can be placed on adjacent unit or one of the brackets for reduced installation costs

- Large mounting holes for securing directly to slotted racking systems

- Slotted housing design allows cable to exit on either end

High-Performance Part Inspection

Engineered with advanced infrared emitter and receiver arrays, this banner part verification array delivers precise detection capabilities even in high-speed, high-volume production settings. Its fast response time and ambient light immunity up to 100,000 lux ensure accurate performance regardless of challenging factory conditions.

Durable and Reliable Construction

Constructed with industrial-grade plastic and aluminum housing complemented by polycarbonate end caps, the sensor boasts superior shock and vibration resistance. With an IP65 rating, it resists dust and water ingress, making it suitable for a wide range of industrial environments.

Effortless Integration and Operation

Featuring both PNP/NPN outputs, LED status indicators for power, output, and alignment, as well as a convenient 2-meter cable, this verification array offers plug-and-play compatibility with existing automation systems. The integrated high-speed processor further enhances throughput and ease of operation.

FAQs of Banner Part Verification Array:

Q: How does the Banner Part Verification Array operate in assembly lines?

A: This verification array uses a series of up to 60 infrared beams spaced at 10 mm to precisely detect, inspect, and verify the presence, position, or dimensions of parts as they move along assembly lines. Its fast response time allows it to keep up with production speeds up to 2000 parts per minute.Q: What are the primary benefits of using this verification array in industrial automation?

A: Key advantages include high detection accuracy, rapid response under 1 ms, robust ambient light immunity up to 100,000 lux, and sturdy construction that withstands shocks and vibrations. These features minimize downtime and ensure consistent quality in part inspection and verification tasks.Q: When should I use this sensor array instead of other detection solutions?

A: Choose this array when you need precise, high-speed part verification in environments where reliability, resistance to harsh conditions, and minimal maintenance are criticalideal for automated assembly lines requiring fast, accurate detection and easy status monitoring.Q: Where can the verification array be installed within a production facility?

A: The array can be bracket or panel mounted alongside conveyor belts, robotic cells, or inspection stationsanywhere accurate part detection and verification are essential within your production or assembly workflow.Q: What is the integration process for connecting the verification array to existing automation systems?

A: The device supports both PNP and NPN transistor output types, allowing flexible interfacing with a wide range of PLCs and controllers. The included 2-meter cable provides easy wired connectivity, and the LED indicators facilitate straightforward alignment and diagnostic checks during installation.Q: How does the sensor maintain performance in environments with high ambient light?

A: With ambient light immunity rated up to 100,000 lux, the array reliably detects parts even in brightly lit or outdoor production areas, ensuring consistent operation without false triggers from external lighting sources.Q: What features make maintenance and troubleshooting easier for operators?

A: LED indicators for power, output, and alignment status deliver instant visual feedback, simplifying alignment, fault detection, and ongoing maintenance for operators and technicians.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese